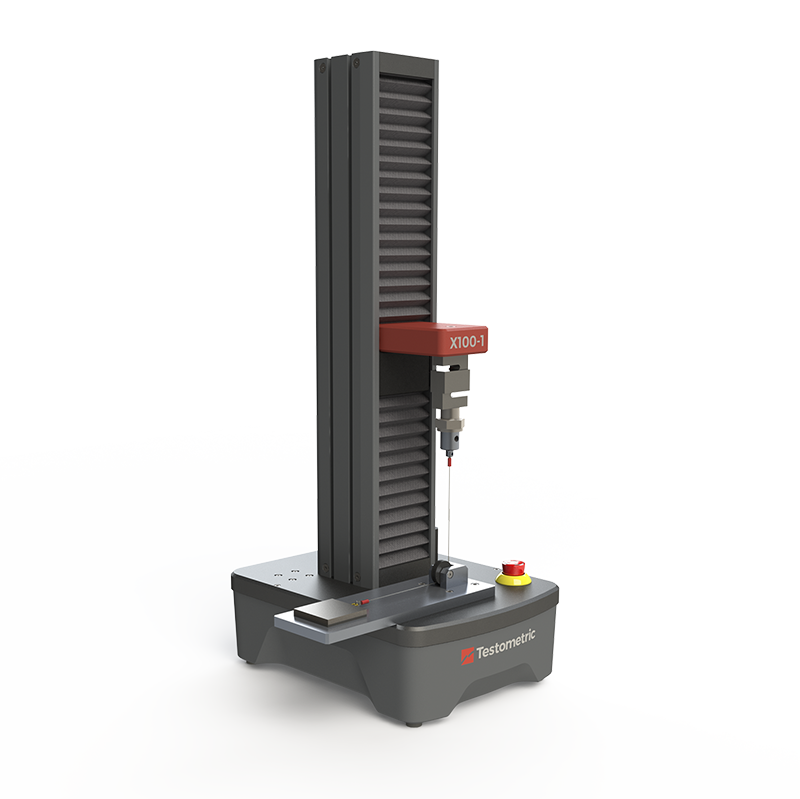

X100-COF - Friction Testing

Dedicated friction testing model based on the X100-1 Universal Testing Machine, complete with friction slide and 200g sled in accordance with numerous international standards such as BS EN ISO 8295, ASTM D1894 and TAPPI T549. Featuring full computer control and precision AC servo drive system, the universal design allows the machine to be easily adapted for other test types (tensile, compression etc.) using Testometric’s extensive range of grips and fixtures.

Machine Software

All machines are supplied with our comprehensive WinTest-Analysis EC software package, allowing full PC control and the ability to create and store complex test routines.

Made to Measure

- Fully digital testing system with high precision control and accuracy, includes automated computer control of test methods giving simplicity of operation.

- High resolution load cells with accuracies better than +/-0.5% down to 1/1000th of the load cell capacity.

- Automatic recognition of load cells and extensometers, with on-device storage of calibration parameters.

- Software calibration check facility for instant verification of machine accuracy.

- 800% overload capability of load cells without damage.

- High efficiency pre-loaded self cleaning ballscrews for fast, quiet testing. Fitted with sealed for life lubricated end bearings.

- Crosshead guidance system providing precise alignment and smooth running.

- Precision crosshead control via digital AC servo drive and brushless servo motor giving maintenance free operation and 23-Bit positional control.

- High speed data collection systems for up to 4 synchronous channels.

- Integral load cell cable routing in machine column to eliminate snagging and prevent cable damage.

- 6 I/O channels for additional devices such as extensometers, micrometers, calipers, balances etc.

- High stiffness loading frames with solid specialised steel crossheads and rigid extruded support columns with T-slots for accessory mounting.

- Overload, overtravel and impact protection.

- Telescopic covers giving additional protection for ballscrews against dust and testing debris.

- Small footprint design, giving economy of bench and floor space.

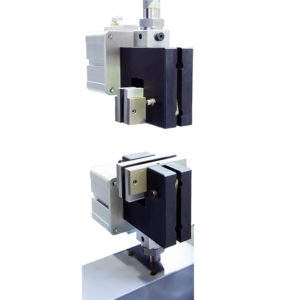

- Extensive range of grips and fixtures for tension, compression, flexural, shear, peel and product testing etc.

- A wide range of contacting and noncontacting extensometers is available including laser and video models.