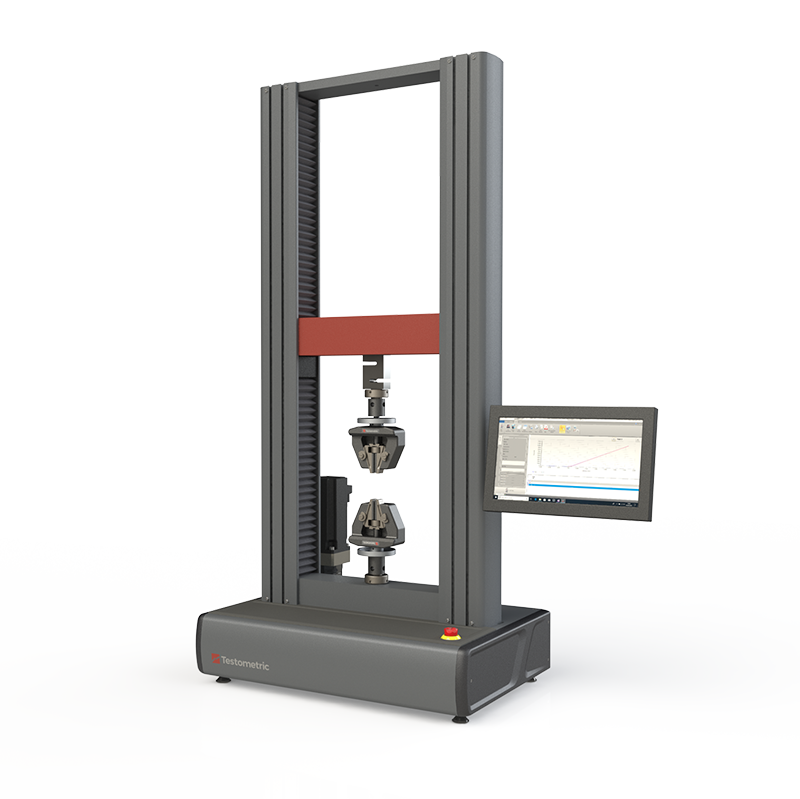

X500 - Machine

Machine Software

All machines are supplied with our comprehensive WinTest-Analysis EC software package, allowing full PC control and the ability to create and store complex test routines.

Made to Measure

- Fully digital testing system with high precision control and accuracy, includes automated computer control of test methods giving simplicity of operation.

- High resolution load cells with accuracies better than +/-0.5% down to 1/1000th of the load cell capacity.

- Automatic recognition of load cells and extensometers, with on-device storage of calibration parameters.

- Software calibration check facility for instant verification of machine accuracy.

- 800% overload capability of load cells without damage.

- High efficiency pre-loaded self cleaning ballscrews for fast, quiet testing. Fitted with sealed for life lubricated end bearings.

- Crosshead guidance system providing precise alignment and smooth running.

- Precision crosshead control via digital AC servo drive and brushless servo motor giving maintenance free operation and 23-Bit positional control.

- High speed data collection systems for up to 4 synchronous channels.

- Integral load cell cable routing in machine column to eliminate snagging and prevent cable damage.

- 6 I/O channels for additional devices such as extensometers, micrometers, calipers, balances etc.

- High stiffness loading frames with solid specialised steel crossheads and rigid extruded support columns with T-slots for accessory mounting.

- Overload, overtravel and impact protection.

- Telescopic covers giving additional protection for ballscrews against dust and testing debris.

- Small footprint design, giving economy of bench and floor space.

- Extensive range of grips and fixtures for tension, compression, flexural, shear, peel and product testing etc.

- A wide range of contacting and noncontacting extensometers is available including laser and video models.