ASTM D638: Standard for Tensile Plastic Testing

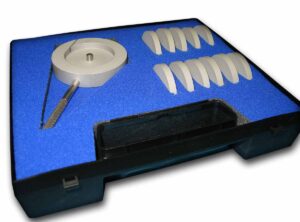

ASTM 638 covers the determination of tensile properties of standard and reinforced plastics in the form of dumbbellshaped test specimens when tested under defined conditions. This plastic testing standard is designed to produce tensile property data for the control and specification of plastic materials and is useful for qualitative characterisation and for research and development.

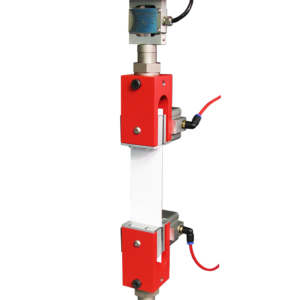

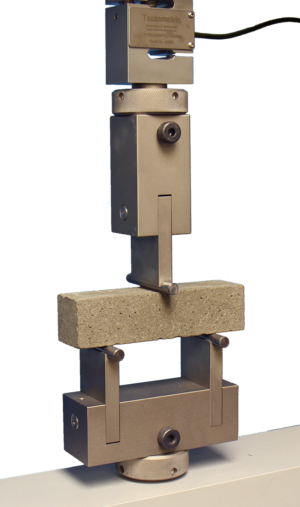

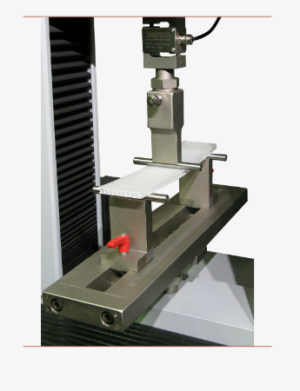

A universal testing machine with constant-rate-of-crosshead movement is used with either fixed or self-aligning grips. Different specimen clamps can be utilised and are selected according to the material to be tested. Testometric can offer manual, self-tightening or pneumatic clamps with a variety of gripping surfaces such as plain rubber, polyurethane, plain metal, serrated faces, textured faces and many more. Some plastic materials can be highly sensitive to mis-alignment or surface stress which makes it imperative that the correct gripping solution is used.

A load cell is used to measure the force applied to the test specimen when loaded in the grips. ASTM D638 requires the accuracy to be equal to or better than +/- 1% of the indicated force value and the accuracy of the testing machine shall be verified in accordance with ASTM E4. All Testometric load cells have an accuracy better than +/- 0.5% of indicated force

down to as low as 1/1000th of the full load capacity of the cell, which means that a single load cell offers the flexibility to test specimens over a large strength range.

For certain material properties tested according to ASTM D638 a higher level of accuracy is required from extension measurements compared to the extension indicated by crosshead movement. In these cases an extensometer can be used to determine the distance between two designated points within the gauge length of the test specimen. Testometric manufactures a large range of contact and non-contact extensometers that meet the accuracy classification requirements for all type of plastics, ranging from very rigid reinforced plastics to high-extension elastomers.

Calculations related to ASTM D638 include, but are not limited to:

- Tensile strength

- Percentage elongation at yield and break

- Modulus of elasticity

- Secant modulus

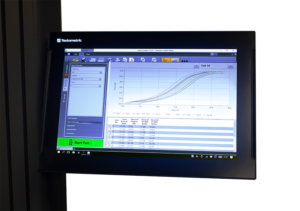

Wintest Analysis EC software is a fully integrated package that supports all industry standards including ASTM D638.

Testometric can provide software with the necessary test standards pre-installed for ease of use for the end user when setting the machine up for testing.

Common international standards for tensile testing:

BS EN ISO 527-1: Plastics. Determination of tensile properties. General Principles.

ASTM D882: Standard Test Method for Tensile Properties of Thin Plastic Sheeting.

Take a look at the most common products used by this industry:

-

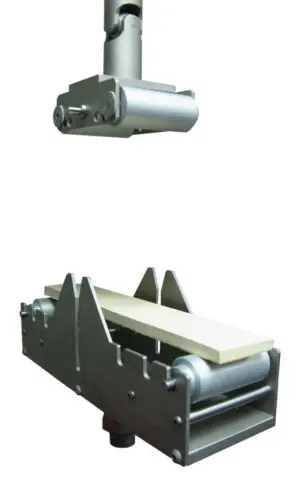

FB4 - Fixed Span 4 Point Bend Fixture

Quick View -

FB1015 - 3 Point Bend

Quick View -

FB1288-3 - Glass Bend Fixture

Quick View -

GRCBEND - Adjustable span 4 point bend fixture for testing glass-fibre re-inforced concrete samples.

Quick View -

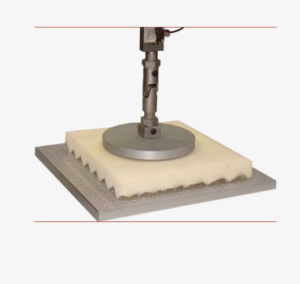

INDHARD - Indentation Hardness Fixture

Quick View -

IPC3 - Integral Touch Screen Panel PC

Quick View -

LDT - Laser Displacement Transducer

Quick View -

PBEND - Variable span bend fixture for plywood.

Quick View -

PP - Parallel Platen Fixture

Quick View -

RCT - Ring crush fixture

Quick View -

VB12390 - 3-Point Bend Fixture for Concrete 100 to 600mm span for concrete to BS EN 12390-5

Quick View

ASTM D638 Plastic Testing FAQs

What is the ASTM D638 standard for plastic testing?

What type of materials can be tested using ASTM D638?

ASTM D638 applies to a wide range of plastic materials, including thermoplastics, thermosetting plastics, and reinforced composites. The standard is primarily used for rigid and semi-rigid plastics.

How does Testometric’s equipment support ASTM D638 testing?

Testometric’s universal testing machines are fully compatible with ASTM D638, providing precise control of forces from 15N to 1000kN. Our machines are equipped with advanced software to record and analyse key tensile properties as required by the standard.

What specimens are required for ASTM D638 testing?

The ASTM D638 standard specifies the use of a standard dumbbell-shaped specimen. Testometric’s machines are designed to handle these specimens accurately, ensuring reliable and consistent results.

How are tensile properties measured in ASTM D638?

During ASTM D638 testing, the plastic specimen is subjected to tensile force until it breaks. Testometric’s machines measure the tensile strength, elongation at break, and modulus of elasticity, providing detailed data for material evaluation.

What grips and fixtures are needed for ASTM D638 testing?

Testometric provides a range of grips and fixtures suitable for ASTM D638 testing. These grips are designed to securely hold the specimen during the test, preventing slippage and ensuring accurate tensile measurements.

How accurate is ASTM D638 testing using Testometric’s machines?

Testometric’s machines are engineered for high accuracy and repeatability, ensuring that the tensile properties measured during ASTM D638 testing meet the required precision standards for research and quality control applications.

What kind of support does Testometric offer for ASTM D638 testing?

Testometric offers full support for ASTM D638 testing, including equipment setup, calibration services, software integration, and ongoing technical assistance to ensure that your testing process is efficient and compliant with the standard.